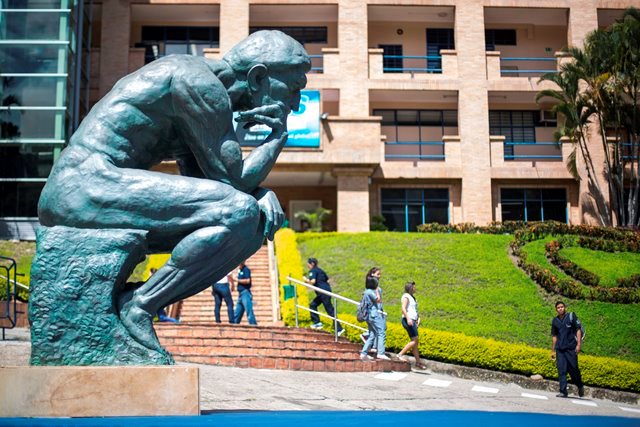

LA UDES PUBLICA

- Fecha de publicación:

- 2025-08-01

- Tipo:

- Article

- Número de artículo:

- 126454

- Identificación:

- SCOPUS_ID:105002374176

- eID:

- 2-s2.0-105002374176

- Nombre de la revista:

- Applied Thermal Engineering

- Autor(es) UDES:

- Acevedo J.

- Otros Autores:

- Gomez Vásquez R.D., Rhenals-Julio J.D., Mendoza J.M., Bula Silvera A.J.

- Autor Principal:

- Gomez Vásquez R.D.

- Áreas del conocimiento:

- Energy Engineering and Power Technology, Mechanical Engineering, Fluid Flow and Transfer Processes, Industrial and Manufacturing Engineering

Cuartil

Q1

- Ranking

- 2017

- Tipo

- Journal

- ISSN

- 13594311

- Región

- Western Europe

- País

- United Kingdom

- Volumen

- 272

- Cobertura

- 1996-2023

Bogotá

Cra. 14 N° 80-35

PBX: (+57) (601) 6914004

Línea Directa Interesados Programas: (601) 6914104

Horario de Atención: lunes a viernes de 7:00 a.m - 12:00 m. y de 2:00 p.m a 6:00 p.m

Pregrados

Universidad de Santander UDES. Vigilada Mineducación.

Resolución otorgada por el Ministerio de Educación Nacional: No. 6216 del 22 de diciembre de 2005 / Personería Jurídica 810 de 12/03/96.

Institución sujeta a inspección y vigilancia por el Ministerio de Educación Nacional. Resolución 12220 de 2016.

Notificaciones administrativas y judiciales:

Copyright © 2021 - Todos los derechos reservados